Electric Concrete Vibrators

Electric Concrete Vibrators

VIBER® Internal Electric Concrete Vibrators date back to the 1920’s – they were used in the building of the Hoover Dam. Our current rugged Made-in-USA VMK Electric motors are manufactured employing the latest technology and using all efficient motor components.

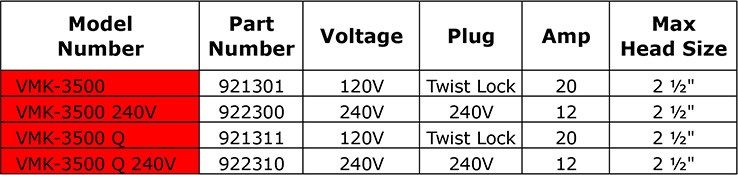

VMK Models use 120V or 240V electric motors to produce high rpm's necessary for concrete consolidation. The largest motor, the VMK-3500, develops 20 amps and is compatible with shaft lengths up to 35' (10.7 m) and heads up to 2½" (63.5 mm) diameter. The 2½" Vibrator Head attached to the VMK-3500 produces an output of 1,955 force pounds (8.70 kN) at 12,000 rpm, with a Radius-of-Action of 24" (610 mm), and a .08" (2 mm) Amplitude Peak-to-Peak. Please review the performance data for details.

The VMK Electric motors connect to Viber's standard flexible shafts and vibrating heads, which are fully interchangeable with our gasoline or pneumatic power units. This provides exceptional flexibility and greatly reduces the amount of the contractor's inventory.

Advantages of the VMK:

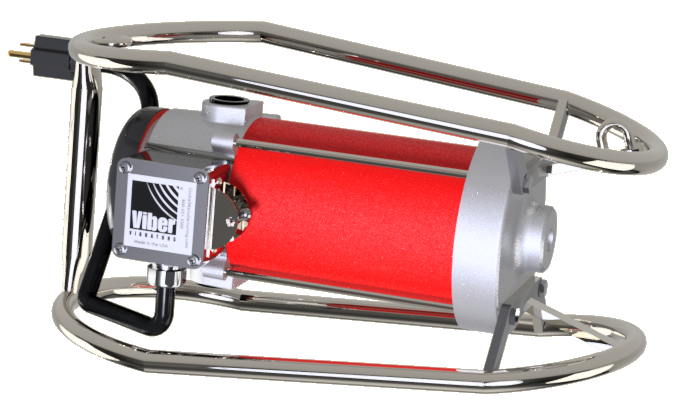

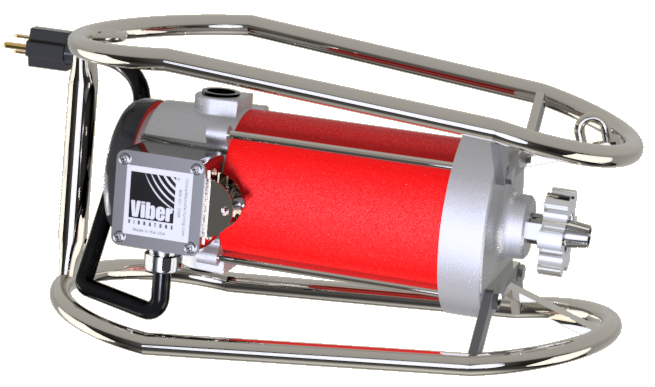

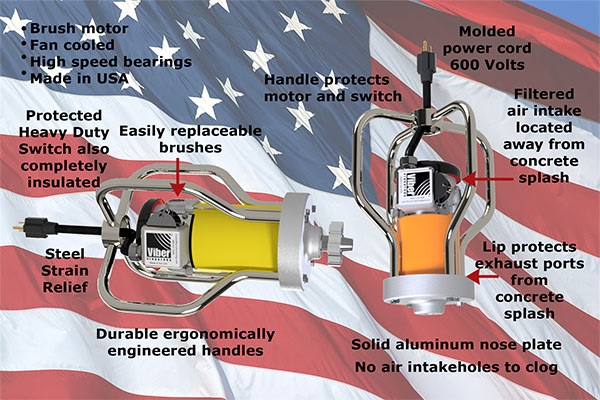

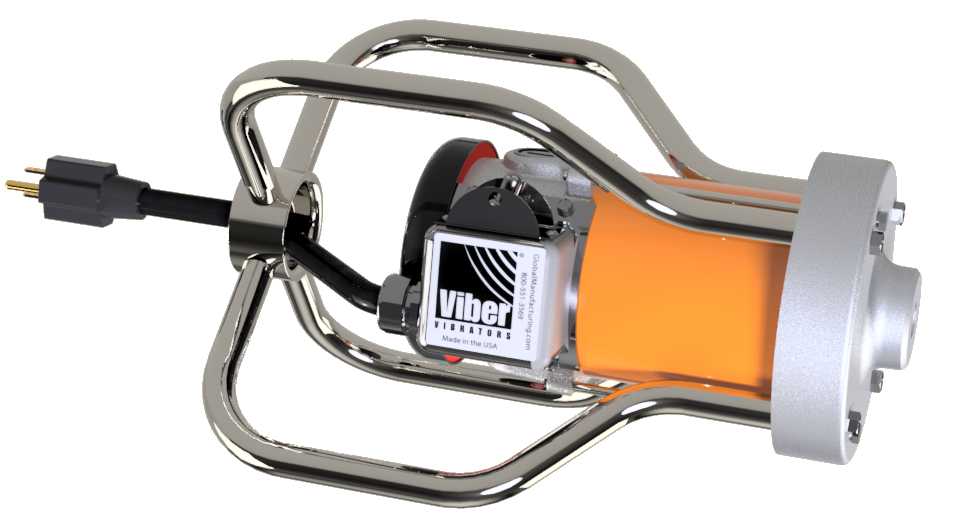

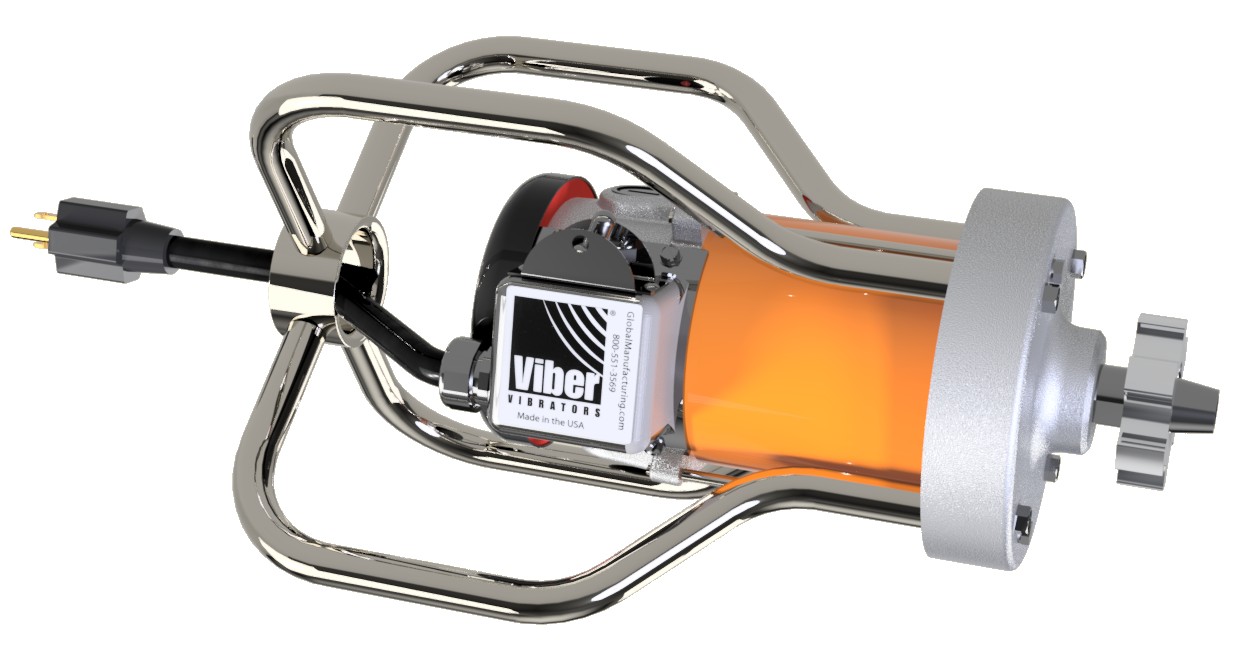

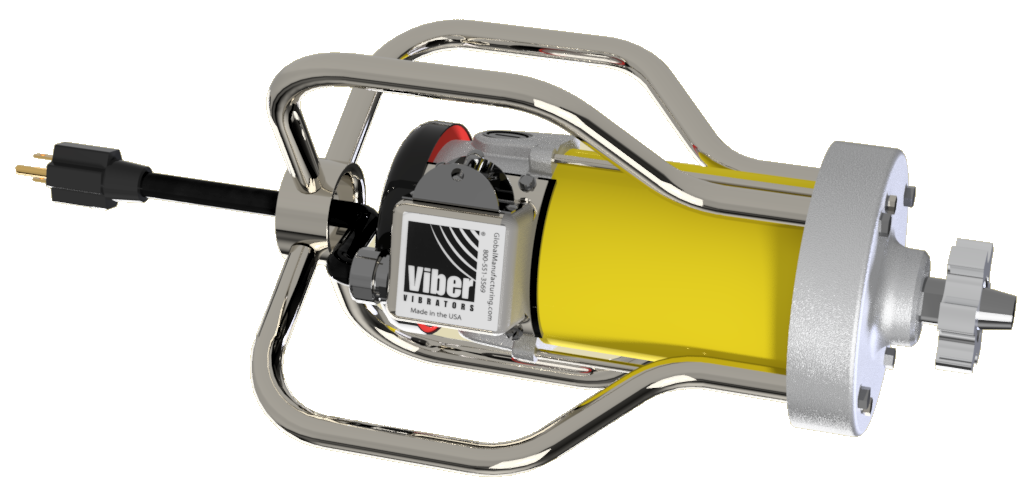

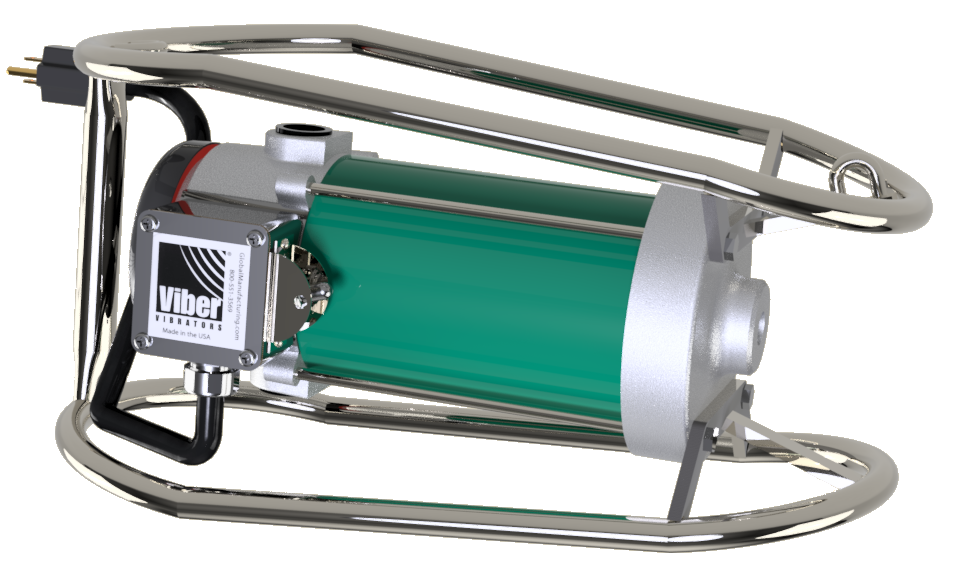

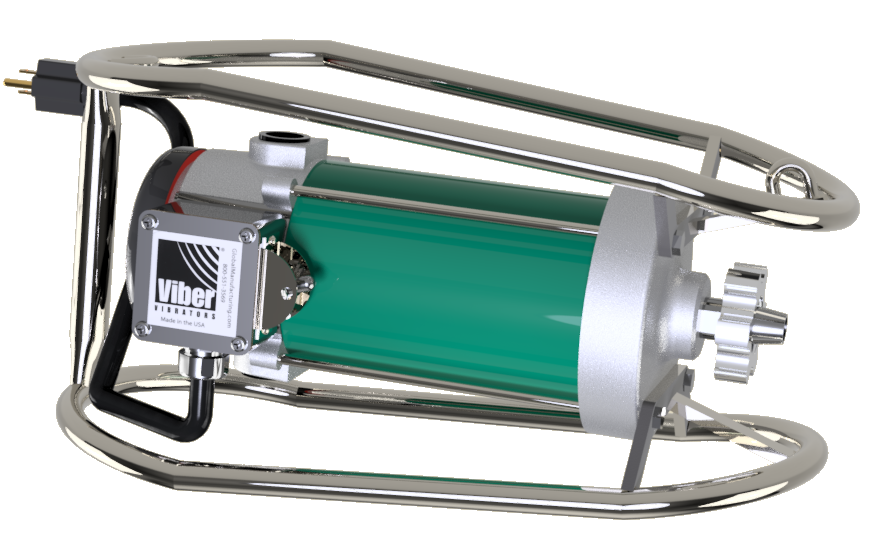

- Rugged Design - Models have cast aluminum housings, epoxy-coated steel bodies and chrome-plated “roll cage” handles, which provides extreme protection and durability when power units are dropped or dragged on the jobsite.

- Protected Exhaust Ports - Cast aluminum faceplate protects exhaust ports from concrete splash. Filtered air intake is located at the rear of the motor to reduce clogging with concrete when operated close to the pour.

- Bearings - Heavy-duty, permanently lubricated high-speed bearings. Motors - VMK Series power units are fan cooled Universal-style 50/60Hz motors available in 120V or 240V models. These powerful motors are capable of producing 10,000-12,000 rpm for optimal concrete consolidation and a perfect finish. VMK Concrete Vibrators are available in four electric motor sizes to be compatible with a wide range of job site applications.

- Brushes are Easy-to-Service - Brushes can be changed with only a screwdriver. No disassembly required.

- Switch - Heavy-duty - fully insulated toggle switch with steel switch guard to protect switch and prevent inadvertent switching off.

- Molded Power Cord - 600V SOOW industrial grade cords have molded plugs and are ozone, oil, and water resistant. Heavy-duty steel strain reliefs. Twist lock plugs available on all models.

- Flex Shaft Extended Lengths - The flexible drives can be coupled together using our coupling to extend them up to 35 feet (10.7 m) or beyond, but care must be used to prevent tight bends in the flex drive and also total weight of the system must be considered.

- Components Completely Interchangeable - All models have identical fittings so they can be paired with any size flexible drive and head. If you stock the gasoline VMG or pneumatic VMP, the flex drives and heads used with those models can be used with your VMK Electric vibrator motor. The interchangeability provides exceptional flexibility and greatly reduces the amount of the contractor’s inventory.

- Optional Quick Disconnect System - All models available with or without quick disconnect system. The quick disconnect allows flexible drives to be switched out without the use of wrenches. No need to pay for a feature if you do not need it.

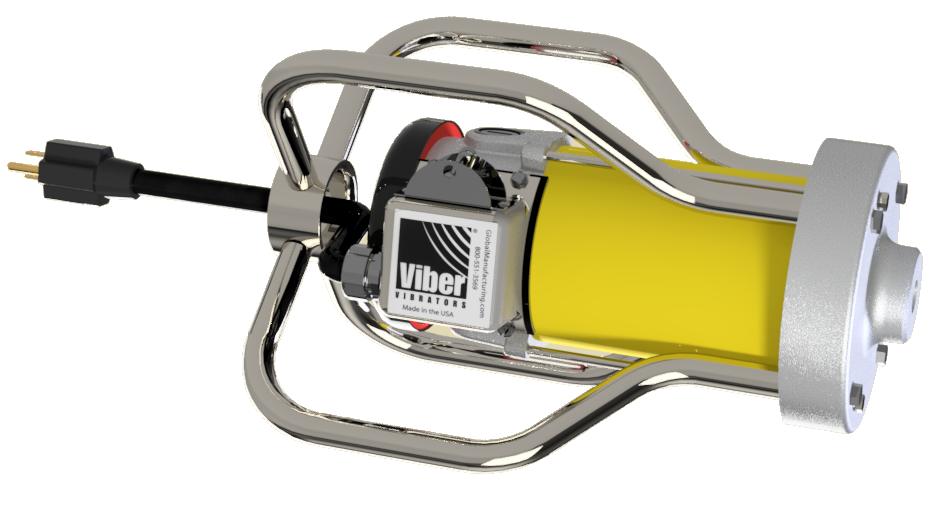

- Viber Vibrators Color-Coded Smart!Parts system takes the guesswork out of matching Vibrator Heads and Motors. See the “Smart Parts Selection Guide”.

Specifications:

- 120V (50/60Hz) or 240V (50/60Hz) AC power.

-

VMK-1500 model is compatible with small and medium-sized heads. Force output range up to 663 force pounds (2.95 kN) at 12,000 rpm, based on which vibrator head is used.

- 120 Volt/10 Amp motor or

- 240 Volt/6 Amp motor

-

VMK-2500 model is compatible with medium-sized heads. Force output range up to 933 force pounds (4.15 kN) at 11,800 rpm, based on which vibrator head is used.

- 120 Volt/15 Amp motor or

- 240 Volt/8 Amp motor

-

VMK-2750 model is compatible with medium and large-sized heads. Force output range up to 1,355 force pounds (6.03 kN) at 11,900 rpm, based on which vibrator head is used.

- 120 Volt/15 Amp motor or

- 240 Volt/9 Amp motors

-

VMK-3500 model is compatible with medium and large-sized heads. Force output range up to 1,955 force pounds (8.70 kN) at 12,000 rpm, based on which vibrator head is used.

- 120 Volt/20 Amp motor or

- 240 Volt/12 Amp motor

- VMK-1500/2500 Operations Manual

- VMK-2750/3500 Operations Manual

- Viber-Electric-Motor-Head-Performance-Data

- Viber-Electric-Motor-Performance-Data

- Electric-Motor-Extension-Cord-Guide

Options:

- Quick Disconnect Systems - motors available with or without quick disconnect systems.

- Twist Lock Plug - standard for the VMK-3500-20 amp motor, but also available in other motor sizes.

Accessories:

- The Quick Disconnect is handy when it is necessary to frequently change flexible drives or to make it easier to store your equipment. The Quick Disconnect allows quick and easy removal of the flexible drive from the power unit without the use of tools. Simply turn the large star-shaped nut clockwise. Order VMK power units with or without this feature. Quick Disconnect kits are available to upgrade any power unit shipped without the feature.

- VQDD Drive Fitting - Order the quick disconnect drive fitting (VQDD) if ordering a VMK with the quick disconnect system. It screws onto the flex drive, which then connects it to the power unit. Or order flex drives with a drive fitting already attached.

- Bearingless, cool running coupling connects one flexible drive to another. You can easily extend our flex drive reach to 35 feet (10.7 m) or more. Longer lengths can be assembled, but tend to get quite heavy ~ approximately 100 lb (45 kg) for 100 ft (30 m). Use caution and avoid sharp bends in the Flex Drive, which will cause excessive wear on the drive and will slow down the engine performance.

VMK Electric Concrete Power Units

All Viber® components use identical fittings so that Viber® components are completely interchangeable. Any flexible drive can be used with any of the power units and any of the heads. The interchangeability provides exceptional flexibility and greatly reduces the amount of the contractor's inventory. Operators select the best combination of head, flex-drive, and power source for their specific requirements

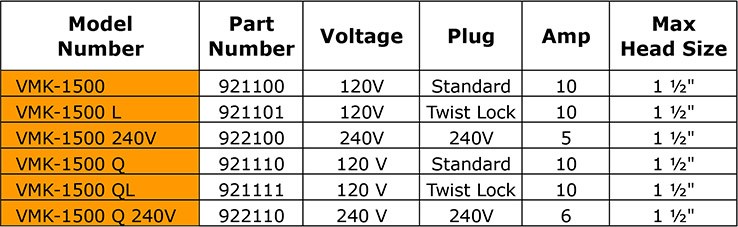

Model: VMK-1500

This electric motor is sized for Heads: ⅞", 1", 1¼", 1½", and the special purpose heads; the 2⅛" Short Head and ⅞" Low Force Head.

Model: VMK-2500

This electric motor is sized for Heads: 1¼", 1½", 1¾", and the special purpose 2⅛" Short Head.

Model: VMK-2750

This electric motor is sized for Heads: 1¼", 1½", 1¾", 2⅛", and 2½".

Model: VMK-3500

This electric motor is sized for Heads: 1¾", 2⅛", and 2½".