Pneumatic Concrete Vibrators

VMP Turbo - a Viber® Pneumatic Turbine Internal Concrete Vibrator

The ONLY pneumatic vibrator that uses standard flex drives and heads! Tolerates dirty air and harsh environments.

How many times have you had to stop a job because your air power tool or air motor was choked off by dirt? Unlike standard vane-driven air motors, which typically seize when dirt is present – "dirty air" passes easily through the turbine wheel, so the VMP Turbo is perfect for harsh environments. What about your tools that need lubrication and stop working because the oil reservoir is never filled? The patented VMP Turbo needs no lubrication saving you the hassle and expense of in-line oilers.

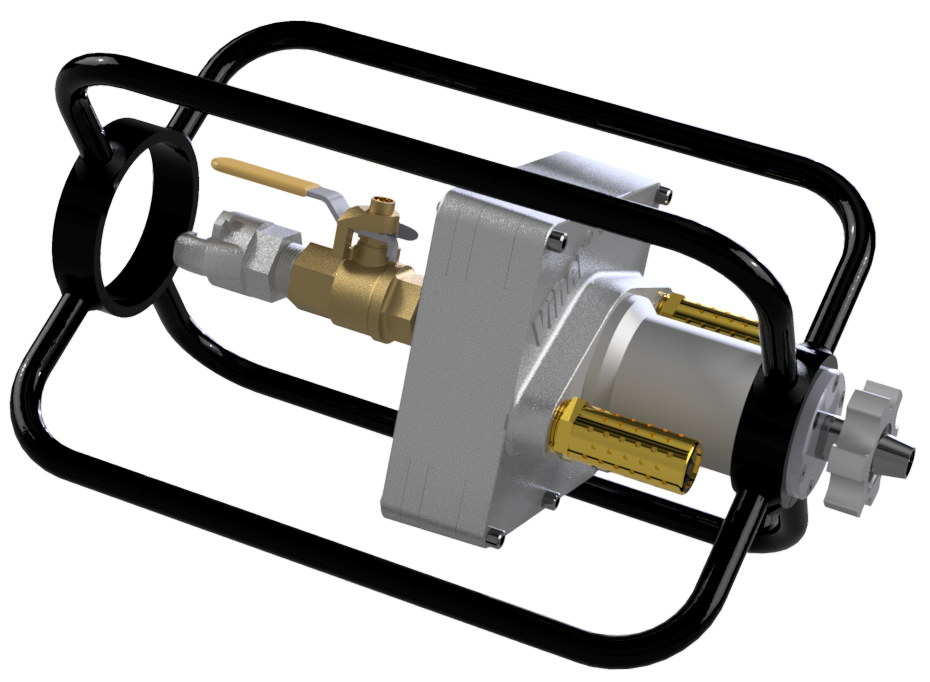

Cage

Cage

This pneumatic power unit is sized for ALL Head sizes.

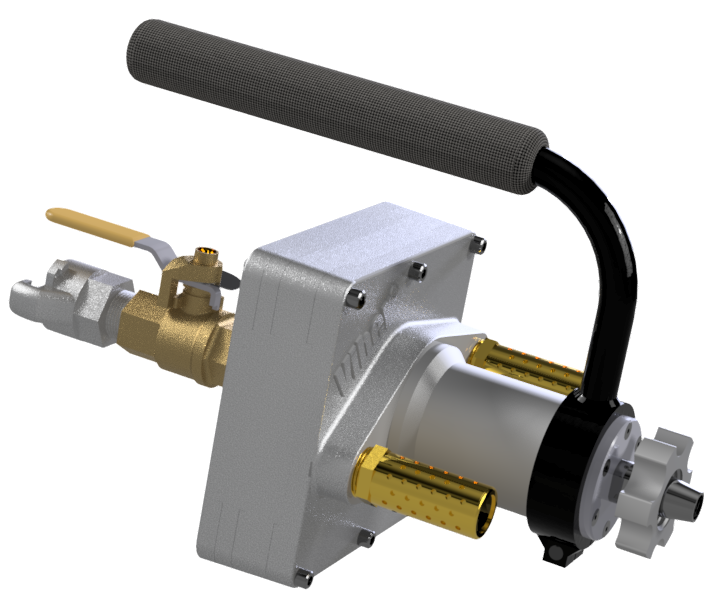

Handle

Handle

The VMP Turbo is a Pneumatic Turbine Power Unit that connects to Viber's standard flex drives and vibrating heads used in concrete construction. The VMP Turbo uses compressed air to turn a turbine wheel producing up to 12,000 rpm and 2.2 horsepower at 100 cfm (2,832 Lpm). It is compatible with flex shaft lengths up to 35' (10.7 m) (or longer if care is used to prevent tight bends in the flex drive) and heads up to 2½" (63.5 mm) diameter. The largest Vibrator Head of 2½" attached to the VMP produces an output of 1,955 force pounds (8.70 kN), with a Radius of Action of 24" (610 mm), and a .08" (2 mm) Amplitude Peak-to-Peak. Please review the performance data for details.

This rugged, highly efficient, powerful unit is the only pneumatic motor in the concrete industry that is completely interchangeable with the electric and gasoline power units and is fully compatible with all Viber® flexible drives and vibrating heads.

Advantages of the VMP Turbo:

- Rugged Design - Durable cast aluminum housings. No plastic housings or covers to break.

- Small, compact and lightweight. Weight comparable to a small to medium sized electric power unit.

- Available with a lightweight handle or a a “roll cage” for full protection and dragging.

- Pneumatic Turbine Motor Tolerates dirty air and harsh environments. Patented turbine technology will allow VMP to continue to run on dirty air that would cause a vane air motor to seize.

- Bearings - Permanently lubricated high-speed bearings.

- No lubrication required - saves the expense of in-line oilers, and the hassle of maintaining them.

- Flex Shaft Extended Lengths - The flexible drives can be coupled together using our coupling to extend them up to 35 feet (10.7 m) or beyond, but care must be used to prevent tight bends in the flex drive and also total weight of the system must be considered.

- Components Completely Interchangeable - The only pneumatic vibrator that uses standard flex drives and heads. All parts have identical fittings so they can be paired with any size flex drive and head. If you stock the gasoline VMG or the electric VMK, the flex drives and heads used with those models can be used with your VMP pneumatic vibrator motor. The interchangeability provides exceptional flexibility and greatly reduces the amount of the contractor's inventory.

- Built-in Quick Disconnect makes it easy to switch drives or heads.

- The VMP Turbo is quieter (80-95 dBA) than vane air motors.

- Viber Vibrators Color-Coded Smart!Parts system takes the guesswork out of matching Vibrator Heads and Motors. See the "Smart!Parts Selection Guide".

-

Flow valve has calibrated scale so it can be set to produce the appropriate vibrations per minute for the

size head being used. Easily powers all VIBER® vibrating heads from ⅞" (22.2 mm) to 2½" (63.5 mm) diameter. The Turbo Dial allows the operator to adjust the VMP for any size vibrator head. Adjust the dial to the head size you are using to ensure accurate force and frequency:

size head being used. Easily powers all VIBER® vibrating heads from ⅞" (22.2 mm) to 2½" (63.5 mm) diameter. The Turbo Dial allows the operator to adjust the VMP for any size vibrator head. Adjust the dial to the head size you are using to ensure accurate force and frequency:

Specifications:

-

Filtered Air

- 30 - 100 psi (2 - 7 bar)

- 35 - 85 cfm (991 - 2,407 Lpm)

- No lubrication required

- 80- 95 dBA

- Maximum Temperature up to 180ºF (82ºC)

- Develops maximum 2.2 HP at 100 cfm (2,832 Lpm)

- Force output range up to 1,955 force pounds (8.70 kN), at 80 psi (5.5 bar) based on Vibrator Head used

- Frequency range up to 12,000 rpm at 30 - 80 psi (2 - 5.5 bar) based on Vibrator Head used

- Compatible with shafts up to 35' (10.7 m) or longer if care is used to prevent tight bends in the flex drive and heads up to 2½" (63.5 mm)

- Maximum Temperature up to 180ºF (82ºC)

- VMP Turbine Operations Manual

- Viber VMP Pneumatic Performance Data

- Viber VMP Head Performance

- VMP Cage Dimensions

- VMP Handle Dimensions

Options:

- VMP available with a Handle or a Cage. The handle makes the VMP easy to manage and lighter weight. The cage encases the turbine motor to protect it from mishandling, abuse, and allows it to be dragged on the ground.

Accessories:

- Bearingless, cool running coupling connects one flexible drive to another. You can easily extend our flex drive reach to 35 feet (10.7 m) or more. Longer lengths can be assembled, but tend to get quite heavy ~ approximately 100 lb (45 kg) for 100 ft (30 m). Use caution and avoid sharp bends in the Flex Drive, which will cause excessive wear on the drive and will slow down the engine performance.

- VQDD Drive Fitting - Order the quick disconnect drive fitting (VQDD) for the flex drive or order flex drives with a drive fitting already attached. The VQDD screws onto the flex drive, which then connects it to the VMP.

The AirHead™ - a Pneumatic Motor-in-the Head

The AirHead™ is a complete internal concrete vibrator system in a single unit. The Vibrating Head contains both an eccentric weight and the power unit, within its housing. The Flexible Drive is replaced by a two-way air hose that delivers the compressed air to the Vibrating Head and then exhausts the air after it passes through the “motor-in-the-head” air motor. This air motor uses a vane to re-direct the air to rotate the eccentric weight within the housing. As the weight rotates, the eccentric rotation produces a powerful high frequency vibration required for concrete consolidation. The AirHead produces 1,684 force pounds (7.49 kN) at 100 psi (7 bar) using 35 cfm (991 Lpm) of air.

Advantages of the AirHead:

- Ready-to-Use - the AirHead™ all-in-one Internal Concrete Vibrator System comes complete with oiler, adjustable on/off valve, and quick disconnect making it a great alternative to electric vibrator systems.

- Rugged design - Made in the USA from durable all-metal components. All wearing parts are hardened for extra-long life.

- Bearings - none required.

- Hose - Specially designed two-way air hose is oil, UV, and abrasion-resistant for durability, ease of use, and long life. Standard length is 10', but custom lengths can be provided upon request. Built-in Universal Twist Claw Coupling allows quick and easy connection to air supply.

- Lubrication - Built-in oiler provides lubrication and ensures long service life.

- Very Versatile - 2 ¼" (63.5 mm) diameter / 13" (330 mm) in length. It can be used on a wide variety of applications.

- Efficient - Uses 35 cfm (991 Lpm) @ 100 psi (7 bar). This unit uses less air than other units on the market.

- Fast and Forceful - the AirHead™ produces high amplitude, high frequency vibration that can easily consolidate low-slump concrete used on structural applications. Produces 1,684 force pounds at a frequency range up to 18,000 rpm @ 100 psi (7 bar).

Specifications:

-

Filtered Air

- 35 cfm (991 Lpm)

- 100 psi maximum (7 bar)

- Lubrication required air tool oil suitable for high speed pneumatic machines.

- 3 - 5 drops per minute - rate is not real important as long as a mist is present at the exhaust

- 90- 95 dBA

- Head is 2¼” (63.5 mm) diameter x 13” (330 mm) long

- Force output range up to 1,684 force pounds (7.49 kN) at 100 psi (7 bar)

- Frequency range up to 18,000 rpm at 100 psi (7 bar)

- Hose - 10 feet (3.05 m) - custom lengths available by request

- Temperature range is -40ºF (-40ºC) to 212ºF (100ºC)

- Viber AirHead Operations Manual

- Viber AirHead Dimensions