Pneumatic

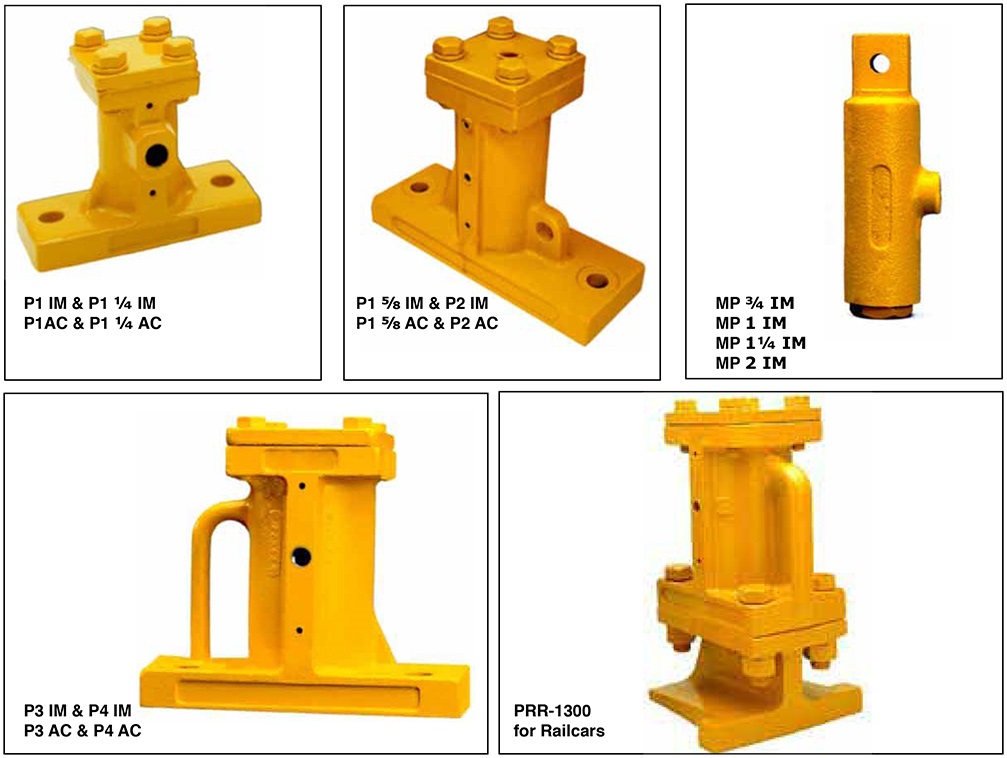

P-Series Piston Vibrators

About P-Series Piston Vibrators

The "P-Series" Piston Vibrators have been the 'standard' over 50 years. These Piston Vibrators use the impact action produced by the oscillating piston to flex the bin wall. This flexing action loosens material stuck to the wall, thus restoring material flow. In general, there are two styles of pneumatic piston vibrators; Impacting (IM) and Air-Cushioned (AC - non-impacting).

The internal piston of impacting models strikes the base of the vibrator, producing the greatest amount of force and frequency. Air-Cushioned models use a cushion of air to dampen the piston movement, so the piston reverses direction before impacting the vibrator base. Therefore, Air-Cushioned models are more quiet but also produce less force and frequency than the Impacting models. Please see:

Advantages of P-Series Piston Vibrators

- Durable - Tough ductile iron housing with chrome plated piston. Chrome plating protects piston from dirt and debris which can scratch and score the piston making it inoperable. Plating also prevents rust that may occur during long periods of non-use.

- Long Life Railcar Models - Piston and housing bore are coated with Teflon® for protection from debris and to decrease the chance of failure due to inadequate lubrication.

- Maximum Force - Impact (IM) models produce maximum force & frequency for size of vibrator.

- Quiet Model Available - Air-Cushioned (AC) model produces less noise than Impact models.

- Energy Efficient - Low air consumption compared to rotary vibrators.

- Versatile - Easy to control force and frequency by adjusting air supply.

- Inexpensive solution to your flow problems.

Specifications

-

Requires filtered air.

- 20-60 psi (1.4 - 4.1 bar) depending on model.

- 1.5-30 CFM (43 - 850 LPM)

- Lubrication required.

- Up to 84 dBA @ 60 psi for Air Cushioned - lower psi and sound level goes down.

- Up to 111 dBA @ 60 psi for Impacting - lower psi and sound level goes down.

- Maximum Ambient Temperature up to 250°F (121°C).

- P-Series Operations Manual

- P-Series Piston Vibrator Dimensions

- P-Series Pistons Dimensional Drawings

Options

- Impact Models (IM) - The piston strikes the base of the vibrator producing the greatest amount of force.

- Air-Cushioned Models (AC) - Quieter than impact models because a cushion of air eliminates metal-to-metal impact.

- Timed Impact Models (TMD) - Delivers one impact at a time on a predetermined signal. Controlled by an electric, electronic, or pneumatic timer, or a programmable controller.

- Railcar Models (PRR-1300) - Comes with a wedge mount bracket to fit railcar pockets. Pistons and bores are Teflon® coated for protection against contaminants and inadequate lubrication. Weights 72 pounds. Generates force output of 423 pounds at 60 psi (4.1 bar) using 20.5 CFM (580 LPM). Air Cushioned only - no metal-to-metal impact.

- Matchplate Models (MP) - Impact type with universal base mount used on foundry matchplates. Internal spring allows any mount orientation.

Accessories

-

Manual Valves:

- 2-way manual ball valve used to turn the vibrator on and off for normal operation.

- 3-way manual ball valve used to turn the vibrator on and off when rapid on/off/on operation is required.

-

Solenoids - For remote or automated control

- Use 2-way normally closed solenoid valve to turn the vibrator on and off for normal operation.

- Use 3-way normally closed solenoid valve when rapid on/off/on operation is required.

- Airline Kits - Required for trouble-free operation and long life of piston vibrators. Includes airline filter, lubricator, and pressure regulator with gauge.

- Internal Spring - Can be added for operating piston in horizontal plane.

- GBF Bracket - Female pocket bracket that accepts universal wedge-shaped male bracket found on portable vibrators such as P-Series Railcar Piston Vibrators.

- Sirometer - Convenient, compact rpm meter for measuring vibrator speed.

Vibrator Selection

Since piston vibrators create material flow by flexing the bin wall, selection of the proper vibrator is based on the bin wall thickness. The thicker the wall the bigger the vibrator needed. If selecting a more quiet Air-Cushioned model you generally use one size larger than an Impacting model sized for the same application. Selection is also based on the combined weight of the chute or moving part of screen and the material inside. Please see: