Shop

Concrete Vibrators

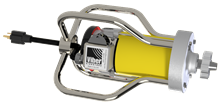

MOTOR VMP TURBO WITH CAGE

Turbine Air Motor - 2.2 hp comes with Quick Disconnect Fitting

Order Flex Drive with Drive Fitting or order fitting separately

https://www.globalmanufacturing.com/pneumatic/

Product Number: 911211

Weight: 17.70 lbs

$1,274.15

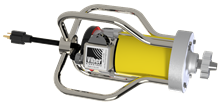

MOTOR VMP TURBO WITH HANDLE

Turbine Air Motor - 2.2 hp comes with Quick Disconnect Fitting

Order Flex Drive with Drive Fitting or order fitting separately

https://www.globalmanufacturing.com/pneumatic/

Product Number: 911212

Weight: 14.90 lbs

$1,104.15

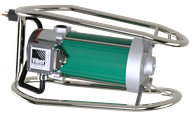

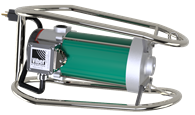

AIRHEAD - VAH36 2 1/4"

Air Motor-in-Head / Head size2¼"

Complete with oiler, adjustable on/off valve, & quick disconnect claw fitting

https://www.globalmanufacturing.com/pneumatic/

Product Number: 916136

Weight: 19.30 lbs

$704.65

MOTOR - VMG 2500BP

Gasoline Engine-Large Backpack-2.5 hp comes with Quick Disconnect Fitting

Order Flex Drive with Drive Fitting or order fitting separately

https://www.globalmanufacturing.com/gasoline/

Product Number: 913250

Weight: 26.80 lbs

$2,540.65

MOTOR VMK 1500 - 10 AMP 120V

Universal Electric Motor with Standard Plug

Max Head Size 1½"

https://www.globalmanufacturing.com/electric/

Product Number: 921100

Weight: 13.00 lbs

$502.35

MOTOR VMK 1500L - 10 AMP 120V TL

Universal Electric Motor with Twist Lock Plug

Max Head Size 1½"

https://www.globalmanufacturing.com/electric/

Product Number: 921101

Weight: 13.20 lbs

$507.45

MOTOR VMK 1500 - 5 AMP 240V

Universal Electric Motor with 240V Plug

Max Head Size 1½"

https://www.globalmanufacturing.com/electric/

Product Number: 922100

Weight: 13.00 lbs

$509.15

MOTOR VMK 1500Q - 10 AMP 120V QD

Universal Electric Motor with Standard Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 1½"

https://www.globalmanufacturing.com/electric/

Product Number: 921110

Weight: 13.40 lbs

$572.90

MOTOR VMK 1500QL - 10 AMP 120V QD/TL

Universal Electric Motor with Twist Lock Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 1½"

https://www.globalmanufacturing.com/electric/

Product Number: 921111

Weight: 13.50 lbs

$578.00

MOTOR VMK 1500Q - 5 AMP 240V QD

Universal Electric Motor with 240V Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 1½"

https://www.globalmanufacturing.com/electric/

Product Number: 922110

Weight: 13.40 lbs

$579.70

MOTOR VMK 2500 - 15 AMP 120V

Universal Electric Motor with Standard Plug

Max Head Size 1¾"

https://www.globalmanufacturing.com/electric/

Product Number: 921150

Weight: 15.70 lbs

$514.25

MOTOR VMK 2500L - 15 AMP 120V TL

Universal Electric Motor with Twist Lock Plug

Max Head Size 1¾"

https://www.globalmanufacturing.com/electric/

Product Number: 921151

Weight: 15.90 lbs

$519.35

MOTOR VMK 2500 - 8 AMP 240V

Universal Electric Motor with 240V Plug

Max Head Size 1¾"

https://www.globalmanufacturing.com/electric/

Product Number: 922150

Weight: 15.70 lbs

$521.05

MOTOR VMK 2500Q - 15 AMP 120V QD

Universal Electric Motor with Standard Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 1¾"

https://www.globalmanufacturing.com/electric/

Product Number: 921160

Weight: 16.10 lbs

$587.35

MOTOR VMK 2500QL - 15 AMP 120V QD/TL

Universal Electric Motor with Twist Lock Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 1¾"

https://www.globalmanufacturing.com/electric/

Product Number: 921161

Weight: 16.20 lbs

$592.45

MOTOR VMK 2500Q - 8 AMP 240V QD

Universal Electric Motor with 240V Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 1¾"

https://www.globalmanufacturing.com/electric/

Product Number: 922160

Weight: 16.10 lbs

$591.60

MOTOR VMK 2750 - 15 AMP 120V

Universal Electric Motor with Standard Plug

Max Head Size 2 1⁄8"

https://www.globalmanufacturing.com/electric/

Product Number: 921200

Weight: 21.60 lbs

$534.65

MOTOR VMK 2750L - 15 AMP 120V TL

Universal Electric Motor with Twist Lock Plug

Max Head Size 2 1⁄8"

https://www.globalmanufacturing.com/electric/

Product Number: 921201

Weight: 21.80 lbs

$539.75

MOTOR VMK 2750 - 8 AMP 240V

Universal Electric Motor with 240V Plug

Max Head Size 2 1⁄8"

https://www.globalmanufacturing.com/electric/

Product Number: 922200

Weight: 21.60 lbs

$646.85

MOTOR VMK 2750Q - 15 AMP 120V QD

Universal Electric Motor with Standard Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 2 1⁄8"

https://www.globalmanufacturing.com/electric/

Product Number: 921210

Weight: 22.00 lbs

$605.20

MOTOR VMK 2750QL - 15 AMP 120V QD/TL

Universal Electric Motor with Twist Lock Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 2 1⁄8"

https://www.globalmanufacturing.com/electric/

Product Number: 921211

Weight: 22.20 lbs

$610.30

MOTOR VMK 2750Q - 8 AMP 240V QD

Universal Electric Motor with 240V Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 2 1⁄8"

https://www.globalmanufacturing.com/electric/

Product Number: 922210

Weight: 22.00 lbs

$717.40

MOTOR VMK 3500L - 20 AMP 120V TL

Universal Electric Motor with Twist Lock Plug

Max Head Size 2 1⁄2"

https://www.globalmanufacturing.com/electric/

Product Number: 921301

Weight: 21.10 lbs

$717.40

MOTOR VMK 3500 - 10 AMP 240V

Universal Electric Motor with 240V Plug & Quick Disconnect Order Flex Drive with Drive Fitting or order fitting separately Max Head Size 2 1⁄2"

https://www.globalmanufacturing.com/electric/

Product Number: 922300

Weight: 24.10 lbs

$719.10

MOTOR VMK 3500QL - 20 AMP 120V QD/TL

Universal Electric Motor with Twist Lock Plug & Quick Disconnect Order Flex Drive with Drive Fitting or order fitting separately Max Head Size 2 1⁄2"

https://www.globalmanufacturing.com/electric/

Product Number: 921311

Weight: 24.50 lbs

$787.95

MOTOR VMK 3500Q - 10 AMP 240V QD

Universal Electric Motor with 240V Plug & Quick Disconnect

Order Flex Drive with Drive Fitting or order fitting separately

Max Head Size 2 1⁄2"

https://www.globalmanufacturing.com/electric/

Product Number: 922310

Weight: 24.50 lbs

$789.65

FLEX DRIVE VDR17-01

1' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930001

Weight: 2.00 lbs

$84.15

FLEX DRIVE VDR17-03

3' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930003

Weight: 3.80 lbs

$109.65

FLEX DRIVE VDR17-05

5' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930005

Weight: 5.70 lbs

$143.65

FLEX DRIVE VDR17-07

7' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930007

Weight: 7.70 lbs

$169.15

FLEX DRIVE VDR17-10

10' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930010

Weight: 10.40 lbs

$211.65

FLEX DRIVE VDR17-14

14' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930014

Weight: 14.60 lbs

$271.15

FLEX DRIVE VDR17-21

21' drive length x 1 1⁄16" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930021

Weight: 21.20 lbs

$390.15

FLEX DRIVE VDR14-01

1' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930201

Weight: 1.20 lbs

$84.15

FLEX DRIVE VDR14-03

3' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930203

Weight: 2.40 lbs

$92.65

FLEX DRIVE VDR14-05

5' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930205

Weight: 3.80 lbs

$109.65

FLEX DRIVE VDR14-07

7' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930207

Weight: 5.20 lbs

$126.65

FLEX DRIVE VDR14-10

10' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930210

Weight: 7.20 lbs

$160.65

FLEX DRIVE VDR14-14

14' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930214

Weight: 10.10 lbs

$203.15

FLEX DRIVE VDR14-21

21' drive length x 7⁄8" diameter

Casing with Core Installed

https://www.globalmanufacturing.com/flex

Product Number: 930221

Weight: 14.70 lbs

$288.15

FLEX DRIVE VDR17-01D

1' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930601

Weight: 2.30 lbs

$118.15

FLEX DRIVE VDR17-03D

3' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930603

Weight: 4.10 lbs

$143.65

FLEX DRIVE VDR17-05D

5' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930605

Weight: 6.00 lbs

$177.65

FLEX DRIVE VDR17-07D

7' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930607

Weight: 8.00 lbs

$203.15

FLEX DRIVE VDR17-10D

10' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930610

Weight: 10.70 lbs

$245.65

FLEX DRIVE VDR17-14D

14' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930614

Weight: 14.90 lbs

$305.15

FLEX DRIVE VDR17-21D

21' drive length x 1 1/16" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930621

Weight: 21.50 lbs

$424.15

FLEX DRIVE VDR14-01D

1' drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930801

Weight: 1.50 lbs

$118.15

FLEX DRIVE VDR14-03D

3 drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930803

Weight: 2.70 lbs

$126.65

FLEX DRIVE VDR14-05D

5' drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930805

Weight: 4.10 lbs

$143.65

FLEX DRIVE VDR14-07D

7 drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930807

Weight: 5.50 lbs

$160.65

FLEX DRIVE VDR14-10D

10' drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930810

Weight: 7.50 lbs

$194.65

FLEX DRIVE VDR14-14D

14' drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930814

Weight: 10.40 lbs

$237.15

FLEX DRIVE VDR21-21D

21' drive length x 7⁄8" diameter

Casing with Core Installed with Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 930821

Weight: 15.00 lbs

$322.15

CASING VCS17-01

1' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932001

Weight: 1.80 lbs

$53.55

CASING VCS17-03

3' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932003

Weight: 3.20 lbs

$75.65

CASING VCS17-05

5' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932005

Weight: 4.70 lbs

$109.65

CASING VCS17-07

7' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932007

Weight: 6.30 lbs

$135.15

CASING VCS17-10

10' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932010

Weight: 8.50 lbs

$160.65

CASING VCS17-14

14' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932014

Weight: 11.80 lbs

$211.65

CASING VCS17-21

21' drive length x 1 1⁄16" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932021

Weight: 17.20 lbs

$322.15

CASING VCS14-01

1' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932201

Weight: 0.90 lbs

$63.75

CASING VCS14-03

3' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932203

Weight: 1.80 lbs

$68.00

CASING VCS14-05

5' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932205

Weight: 2.80 lbs

$82.45

CASING VCS14-07

7' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932207

Weight: 3.80 lbs

$102.00

CASING VCS14-10

10' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932210

Weight: 5.30 lbs

$125.80

CASING VCS14-14

14' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932214

Weight: 7.30 lbs

$159.80

CASING VCS14-21

21' drive length x 7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 932221

Weight: 10.70 lbs

$225.25

CORE VCR04-01

1' length

https://www.globalmanufacturing.com/flex

Product Number: 935001

Weight: 0.30 lbs

$23.80

CORE VCR04-03

3' length

https://www.globalmanufacturing.com/flex

Product Number: 935003

Weight: 0.60 lbs

$25.50

CORE VCR04-05

5' length

https://www.globalmanufacturing.com/flex

Product Number: 935005

Weight: 1.00 lbs

$27.20

CORE VCR04-07

7' length

https://www.globalmanufacturing.com/flex

Product Number: 935007

Weight: 1.40 lbs

$28.90

CORE VCR04-10

10' length

https://www.globalmanufacturing.com/flex

Product Number: 935010

Weight: 1.90 lbs

$39.95

CORE VCR04-14

14' length

https://www.globalmanufacturing.com/flex

Product Number: 935014

Weight: 2.80 lbs

$46.75

CORE VCR04-21

21' length

https://www.globalmanufacturing.com/flex

Product Number: 935021

Weight: 4.00 lbs

$58.65

HEAD VH14-ST 7/8"

7⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950014

Weight: 1.40 lbs

$189.55

HEAD VH16-ST 1"

1" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950016

Weight: 2.10 lbs

$189.55

HEAD VH20-ST 1 1/4"

1¼" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950020

Weight: 3.00 lbs

$198.05

HEAD VH24-ST 1 1/2"

1½" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950024

Weight: 4.20 lbs

$215.05

HEAD VH28-ST 1 3/4"

1¾" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950028

Weight: 5.80 lbs

$223.55

HEAD VH34-ST 2 1/8"

2 1⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950034

Weight: 8.80 lbs

$232.05

HEAD VH40-ST 2 1/2"

2½" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950040

Weight: 14.00 lbs

$254.15

HEAD VH16-RT 1"

1" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950116

Weight: 2.10 lbs

$215.05

HEAD VH20-RT 1 1/4"

1¼" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950120

Weight: 3.10 lbs

$223.55

HEAD VH24-RT 1 1/2"

1½" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950124

Weight: 4.30 lbs

$240.55

HEAD VH28-RT 1 3/4"

1¾" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950128

Weight: 5.80 lbs

$249.05

HEAD VH34-RT 2 1/8"

2 1⁄8" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950134

Weight: 9.00 lbs

$257.55

HEAD VH40-RT 2 1/2"

2½" diameter

https://www.globalmanufacturing.com/flex

Product Number: 950140

Weight: 13.90 lbs

$288.15

GREASE for VIBER CORE 1LB

Use to grease the core in a flex drive

https://www.globalmanufacturing.com/flex

Product Number: 990051

Weight: 1.20 lbs

$27.20

GREASE for VIBER CORE 5LB

Use to grease the core in a flex drive

https://www.globalmanufacturing.com/flex

Product Number: 990055

Weight: 5.70 lbs

$64.60

COUPLER FLEX DRIVE VCP14

for 7⁄8" diameter casing; use to couple together 2 drives

https://www.globalmanufacturing.com/flex

Product Number: 939014

Weight: 0.80 lbs

$126.65

COUPLER FLEX DRIVE VCP17

for 1 1/16" diameter casing; use to couple together 2 drives

https://www.globalmanufacturing.com/flex

Product Number: 939017

Weight: 1.60 lbs

$126.65

VQDK17 - Quick Disconnect Retrofit Kit

Use to add Quick Disconnect system to motors purchased without one

https://www.globalmanufacturing.com/flex

Product Number: 939110

Weight: 0.90 lbs

$118.15

VQDN - Quick Disconnect Nut Fitting

QD Nut

https://www.globalmanufacturing.com/flex

Product Number: 414913

Weight: 0.20 lbs

$34.00

VQDM -Quick Disconnect Motor Fitting

QD Motor Fitting

https://www.globalmanufacturing.com/flex

Product Number: 414912

Weight: 0.20 lbs

$40.80

VQDD - Quick Disconnect Drive Fitting

QD Drive Fitting

https://www.globalmanufacturing.com/flex

Product Number: 414911

Weight: 0.30 lbs

$40.80

Brush for VME Motor - Top Shunt

Brush for universal VME electric motor

https://www.globalmanufacturing.com/electric/

Product Number: 470101

Weight: 0.06 lbs

$7.65

Brush for VME Motor - Side Shunt

Brush for universal VME electric motor

https://www.globalmanufacturing.com/electric/

Product Number: 470103

Weight: 0.06 lbs

$5.10

Brush for VMK-1500 & VMK-2500

Brush for universal VMK electric motor

https://www.globalmanufacturing.com/electric/

Product Number: 470104

Weight: 0.06 lbs

$13.60

Brush for VMK-2750 & VMK-3500

Brush for universal VMK electric motor

https://www.globalmanufacturing.com/electric/

Product Number: 470107

Weight: 0.06 lbs